Energy Crunch

Energy conservation is a cornerstone of Kendall-Jackson's sustainability program. Electricity production is responsible for 35% of all U.S. Green House Gas (GHG) emissions. That means generating power contributes nearly twice as much pollution as all the cars, planes and other forms of transportation in the world.

North Americans alone consume 2.3 trillion pounds of coal each year to generate electricity, which is 18 pounds per day per person. Or to put it another way, a single train carrying that much coal would be 102,000 miles long and reach almost half way to the moon.

(Check out Chris Jordan’s Website and click on the photo to get a better sense of scale.)

I’m not making this stuff up – it’s real. Now don’t get me wrong, I’m not the doom and gloom type, I’d rather spend my time trying to find solutions to problems, but I came across this info and it kind of blew my doors off so I thought I might share it.

Here at Kendall-Jackson we’ve followed a three-step progression to most effectively save energy across all of our operations. It’s kind of like the reduce, reuse, recycle motto you might know for waste materials, but this one’s for energy:

Conserve by simply eliminating wasted energy — turn off office equipment at night and use cold water instead of hot.

Optimize equipment by updating our process to best use the efficient gear we have and then retrofit old, inefficient equipment with new technology.

Produce renewable energy on-site or buy it from third parties.

You might think the first thing to do is to put some solar panels on the roof. Turns out, that’s the last project we should work on after we’ve found every opportunity to reduce the amount of energy we use. This way we’ll need fewer solar panels, in turn requiring fewer natural resources to build those solar panels.

So, we started with conservation and optimization. We performed detailed audits of our buildings, equipment and processes to find every opportunity to save energy; we next recomissioned and retrofitted our buildings.

Recommissioning — or fine tuning — our equipment and processes essentially sets the efficiency clock back to save energy without having to buy lots of new gear. Over time our wineries change from how they were originally designed and built. After 10, 15 or even 20 years almost nothing is operating the way it was originally designed.

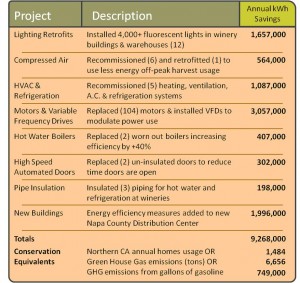

We feel pretty good about our early results. We’re now reducing our GHG production by over 6,600 tons per year. Check out this chart to see where we made the most significant energy savings.